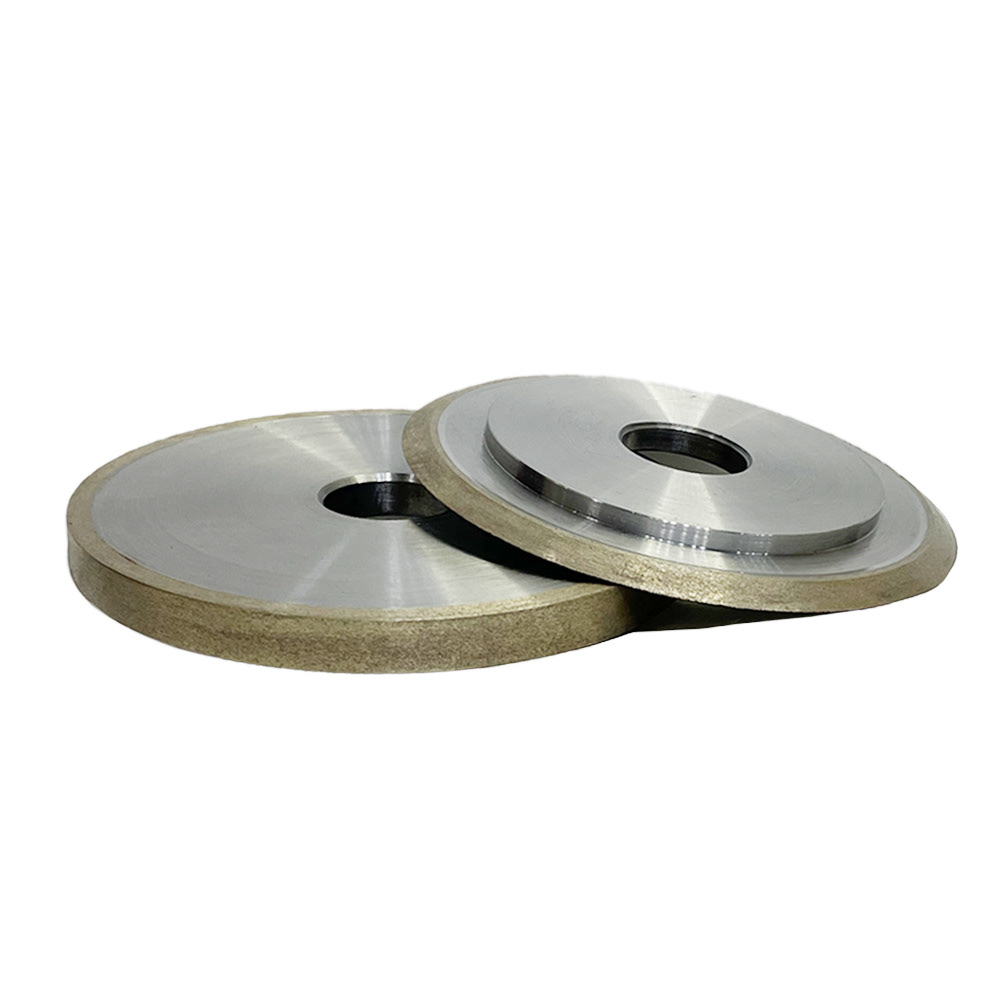

DIAMOND/CBN RESIN BOND GRINDING WHEEL

Features & Advantages

■ Designed for efficient grinding of carbide, ceramics, hardened steel, and superalloys.

■ Resin bond provides sharp cutting action, reduced grinding force, and minimal workpiece burn.

■ Offers stable form retention and high dimensional accuracy during continuous operation.

■ Available in various grit sizes, shapes, and customized specifications to fit CNC grinders and manual grinding equipment.

Benefits for Users

■ Increases machining speed and productivity

■ Extends wheel dressing intervals

■ Produces smooth surface finishes suited for precision tooling and mold applications

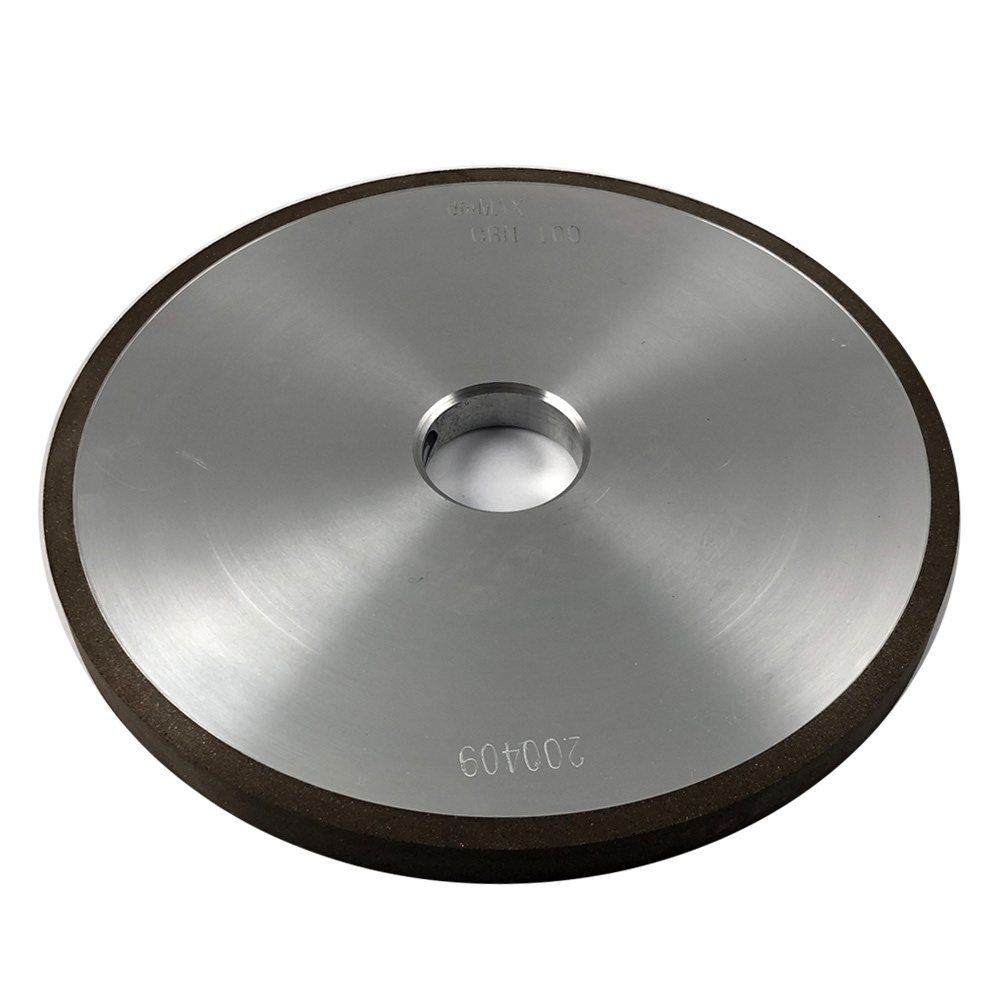

Features & Advantages

■ Designed for efficient grinding of carbide, ceramics, hardened steel, and superalloys.

■ Resin bond provides sharp cutting action, reduced grinding force, and minimal workpiece burn.

■ Offers stable form retention and high dimensional accuracy during continuous operation.

■ Available in various grit sizes, shapes, and customized specifications to fit CNC grinders and manual grinding equipment.

Benefits for Users

■ Increases machining speed and productivity

■ Extends wheel dressing intervals

■ Produces smooth surface finishes suited for precision tooling and mold applications

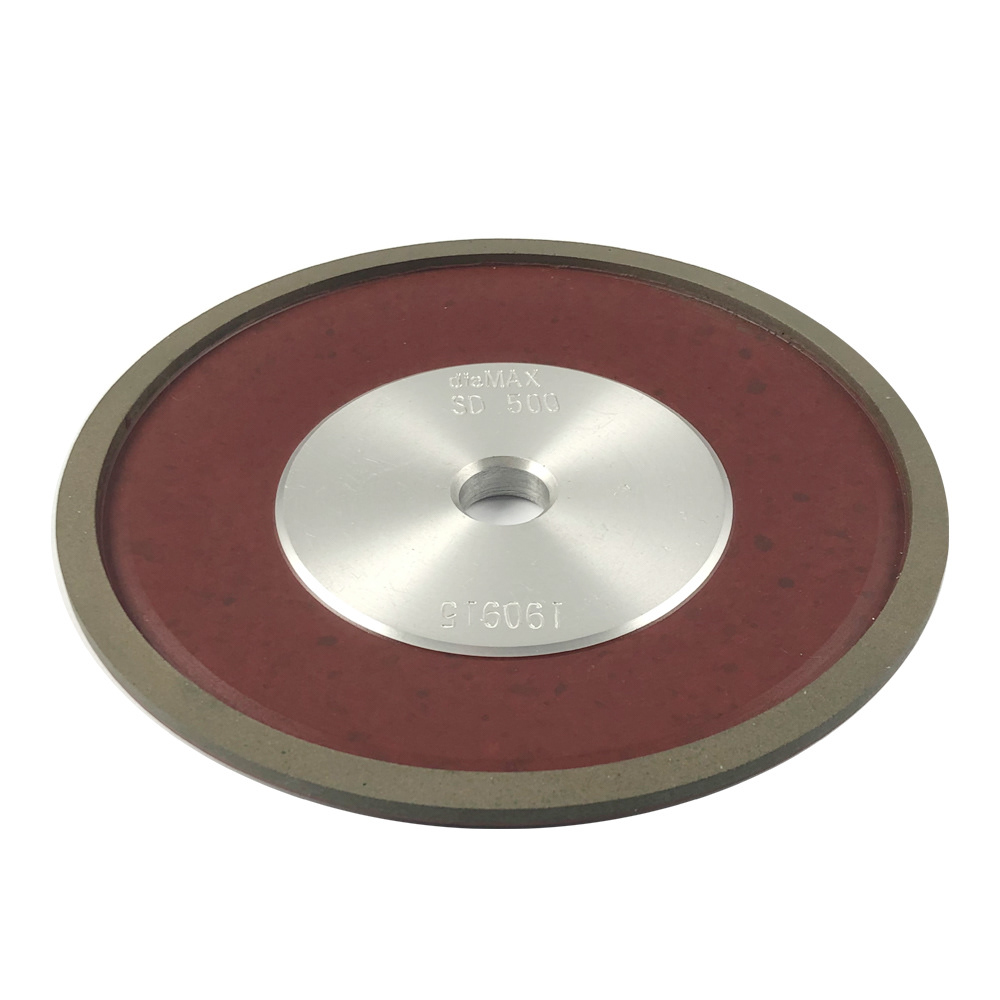

DIAMOND/CBN RESIN BOND OIL STONE

Features & Advantages

■ Fine-grain resin bond composition allows controlled material removal and refined polishing.

■ Ideal for die & mold cavity finishing, tool edge honing, and carbide insert detailing.

■ Maintains uniform abrasive exposure for stable cutting performance over time.

■ Fine-grain resin bond composition allows controlled material removal and refined polishing.

■ Ideal for die & mold cavity finishing, tool edge honing, and carbide insert detailing.

■ Maintains uniform abrasive exposure for stable cutting performance over time.

Benefits for Users

■ Enables precise manual finishing in small, complex geometries

■ Enhances product surface quality and reduces secondary processing

■ Suitable for mold repair, sharpening, and fine finishing tasks

■ Enhances product surface quality and reduces secondary processing

■ Suitable for mold repair, sharpening, and fine finishing tasks

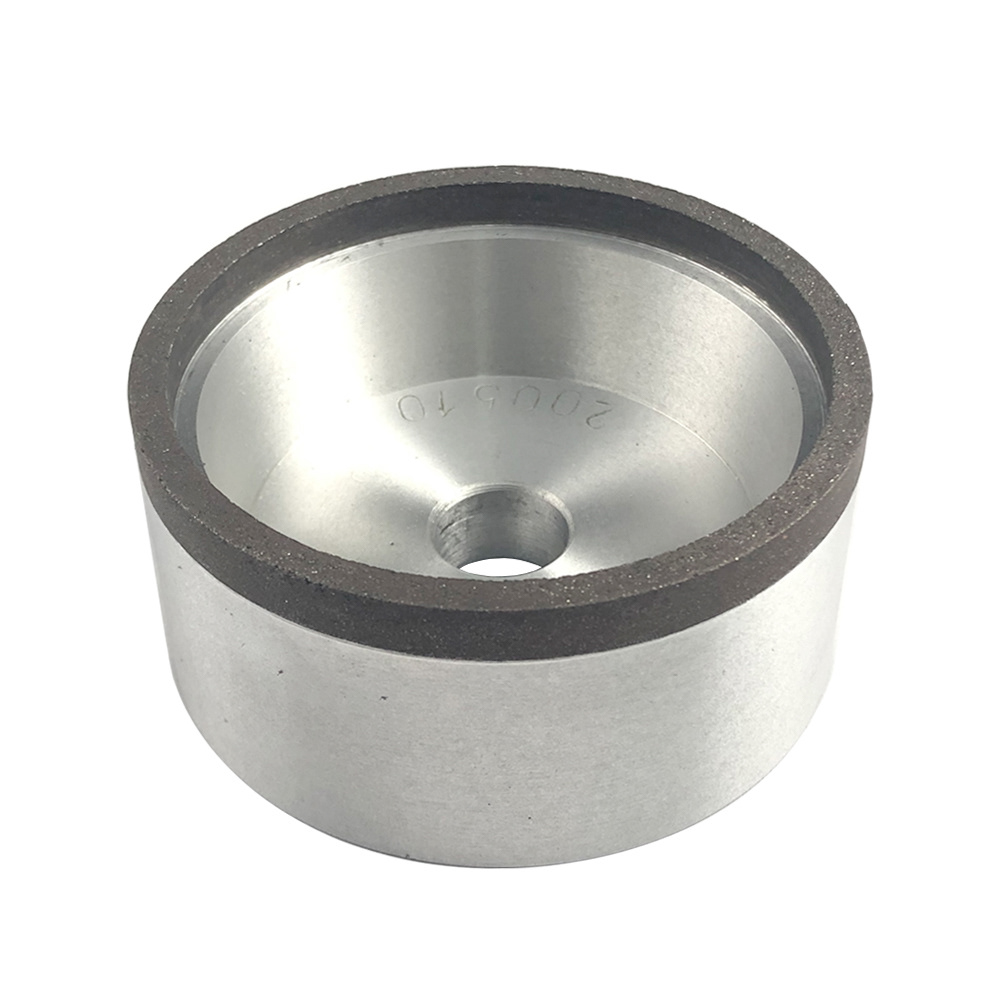

DIAMOND/CBN RESIN BOND MOUNTED POINT

Features & Advantages

Features & Advantages

■ Small-diameter grinding tools designed for internal grinding and fine contour work.

■ Excellent stability at high spindle speeds, reducing vibration and improving control.

■ Resin bond ensures self-sharpening performance and consistent abrasive action.

■ Excellent stability at high spindle speeds, reducing vibration and improving control.

■ Resin bond ensures self-sharpening performance and consistent abrasive action.

Benefits for Users

■ Ideal for finishing internal holes, slots, angles, and miniature features

■ Enhances accuracy in high-precision component manufacturing

■ Reduces time spent on manual adjustment and polishing

■ Enhances accuracy in high-precision component manufacturing

■ Reduces time spent on manual adjustment and polishing