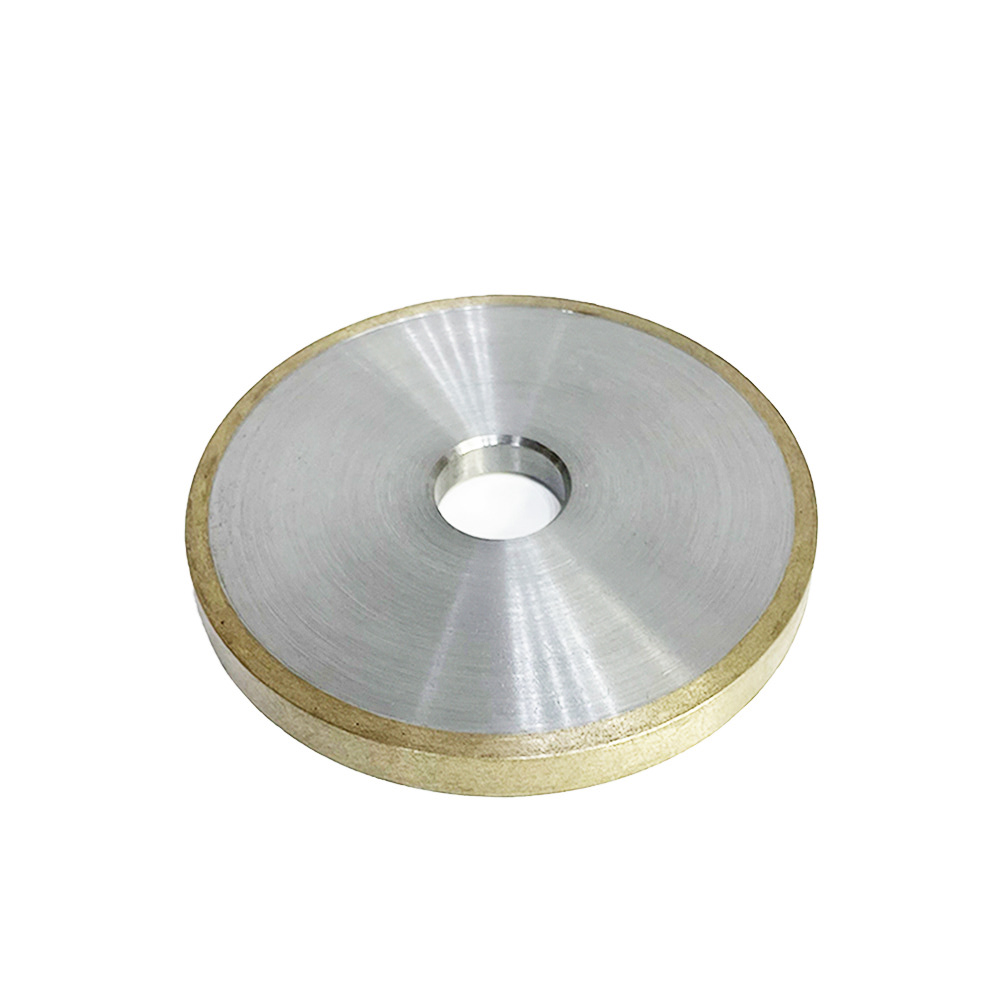

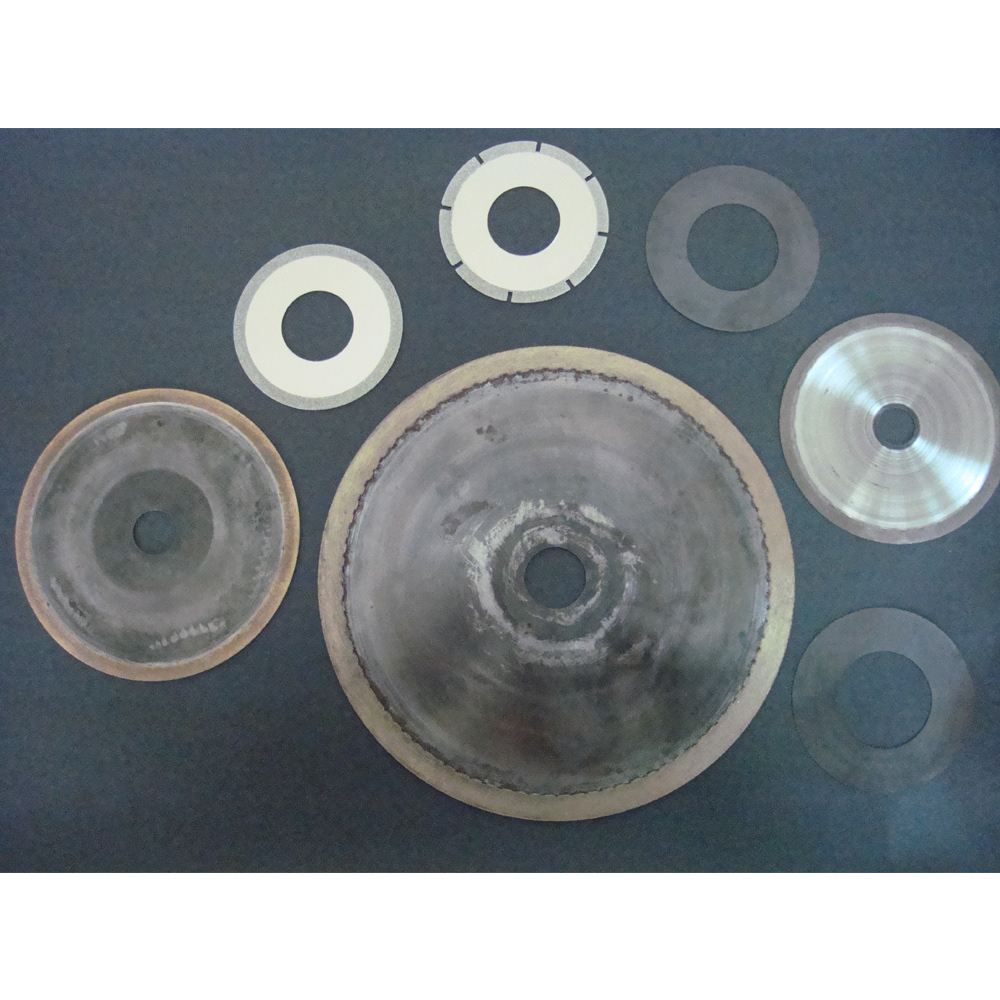

Grinding Wheel

Diamond/CBN Metal Bond Grinding Wheels are engineered for high-efficiency grinding of hard materials, including tungsten carbide, ceramics, hardened steel, and heat-resistant alloys.

Features & Advantages

■ Exceptional wear resistance and long service life

■ Maintains shape and edge precision even under heavy grinding pressure

■ Ideal for surface grinding, internal grinding, and tool sharpening

■ Exceptional wear resistance and long service life

■ Maintains shape and edge precision even under heavy grinding pressure

■ Ideal for surface grinding, internal grinding, and tool sharpening

Benefits for Users

Industrial production lines benefit from reduced wheel changes, stable surface finishing, and consistent tolerance accuracy.

Industrial production lines benefit from reduced wheel changes, stable surface finishing, and consistent tolerance accuracy.

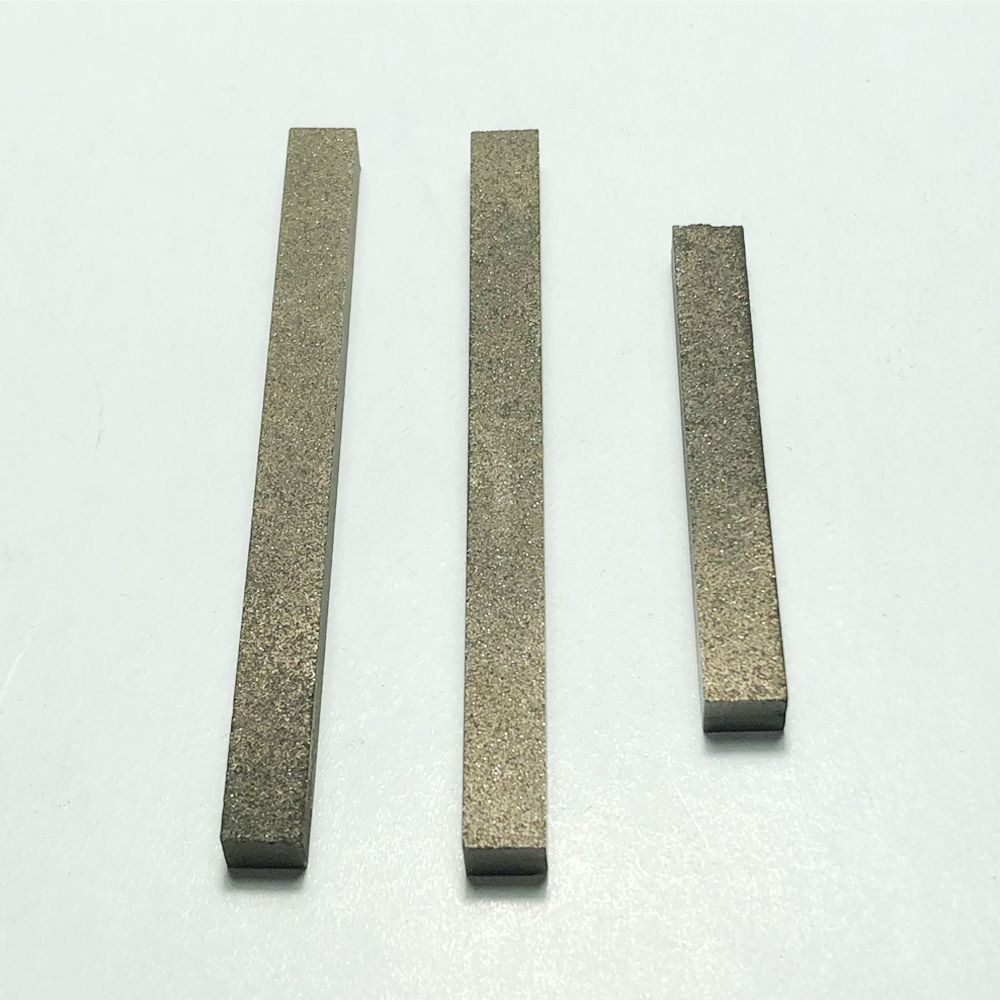

Honing Stone

Metal bond honing stones provide precise dimensional correction and ultra-fine surface finishing for internal diameters and precision bores.

Features & Advantages

■ Uniform abrasive distribution ensures controlled material removal

■ Suitable for high-precision cylinder and bore finishing

■ Supports wet honing for improved smoothness and cooling

■ Uniform abrasive distribution ensures controlled material removal

■ Suitable for high-precision cylinder and bore finishing

■ Supports wet honing for improved smoothness and cooling

Benefits for Users

Improves roundness, cylindricity, and micro-level surface texture—ideal for hydraulic parts, bearings, injectors, and engine components.

Improves roundness, cylindricity, and micro-level surface texture—ideal for hydraulic parts, bearings, injectors, and engine components.

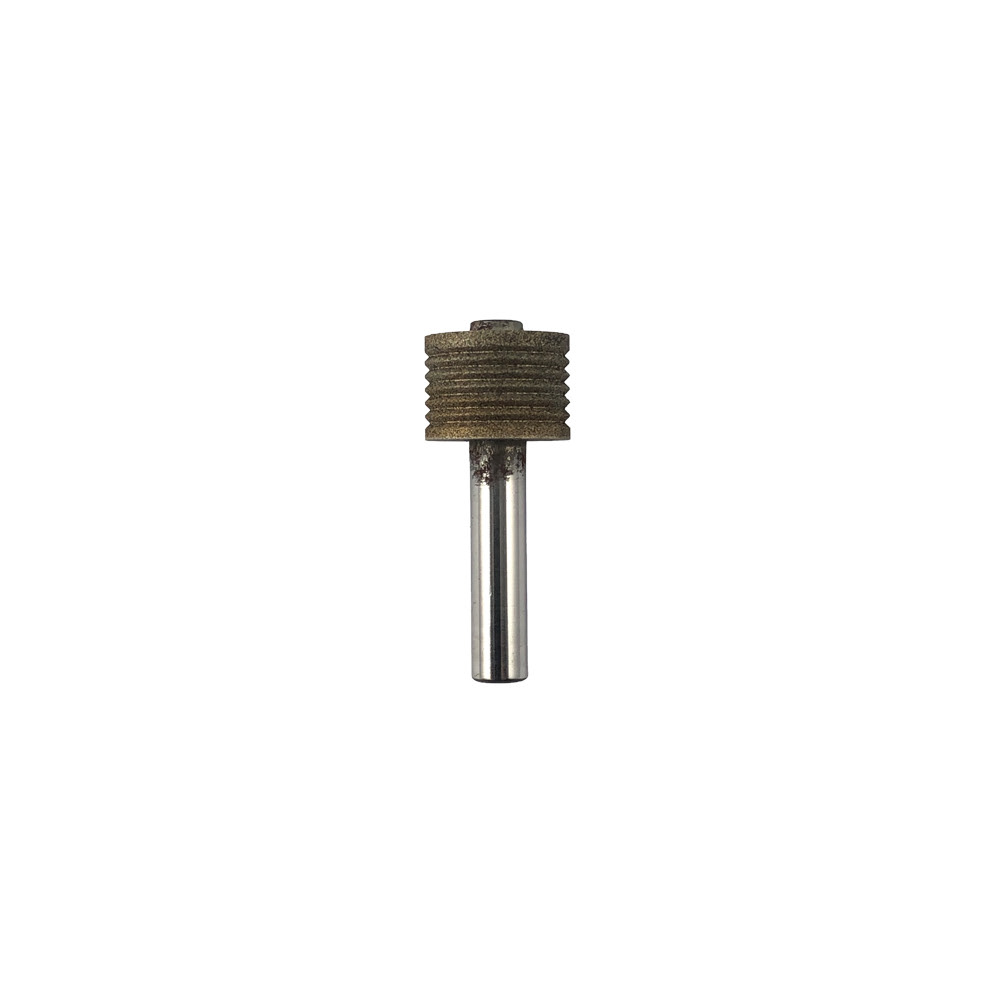

Mounted Point

Diamond/CBN Metal Bond Mounted Points are designed for internal grinding of narrow slots, holes, and complex internal geometries.

Features & Advantages

■ High rigidity ensures stable cutting at high RPM

■ Maintains form accuracy even with prolonged use

■ Available in multiple shapes and custom specifications

■ High rigidity ensures stable cutting at high RPM

■ Maintains form accuracy even with prolonged use

■ Available in multiple shapes and custom specifications

Benefits for Users

Suitable for precision finishing in mold cavities, dies, medical instruments, and micro-machined components.

Suitable for precision finishing in mold cavities, dies, medical instruments, and micro-machined components.

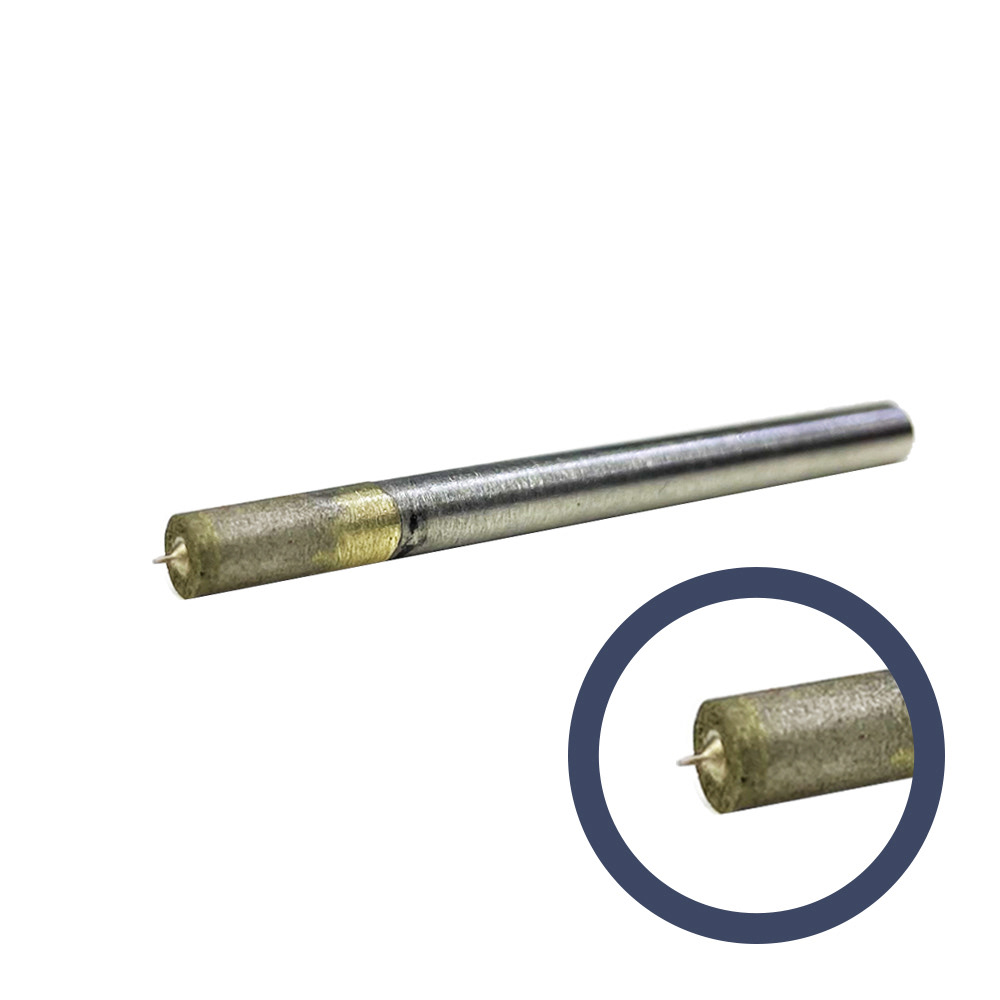

Multi-Point Diamond Dresser

This dresser integrates multiple diamond cutting points to efficiently true and condition grinding wheels for optimal cutting action.

Features & Advantages

• High durability and distributed abrasion reduce wear

• Maintains wheel shape and grinding sharpness

• Ideal for regular dressing in automated production

• High durability and distributed abrasion reduce wear

• Maintains wheel shape and grinding sharpness

• Ideal for regular dressing in automated production

Benefits for Users

Improves grinding consistency while lowering maintenance and tool replacement costs.

Improves grinding consistency while lowering maintenance and tool replacement costs.

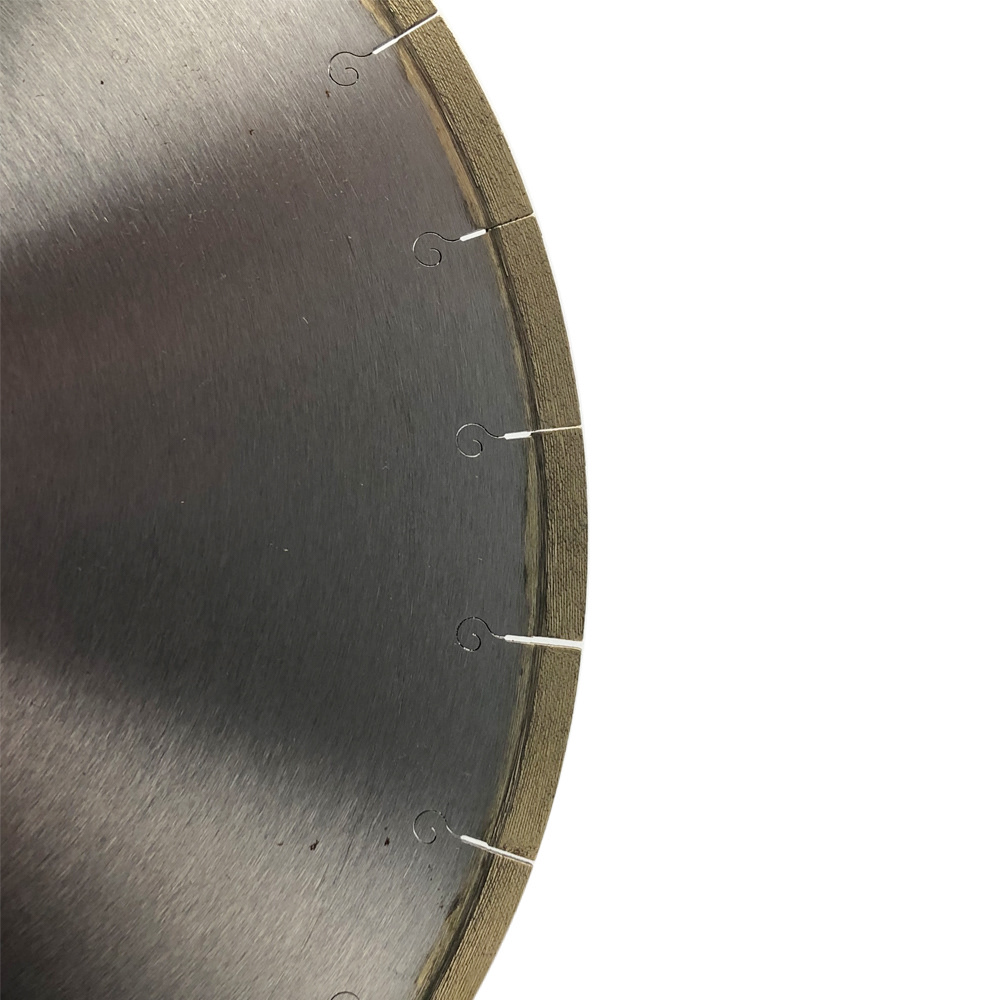

Blade Saw

Diamond/CBN Metal Bond Blade Saws provide clean, stable cutting of hard, brittle, and high-value materials such as ceramics, carbide, composites, and silicon.

Features & Advantages

■ Strong bond ensures edge stability and long blade life

■ Produces clean edges with minimal chipping

■ Available in thin-kerf designs for reduced material waste

■ Strong bond ensures edge stability and long blade life

■ Produces clean edges with minimal chipping

■ Available in thin-kerf designs for reduced material waste

Benefits for Users

Delivers superior cutting precision and efficiency, supporting both manual equipment and automated sawing systems.

Delivers superior cutting precision and efficiency, supporting both manual equipment and automated sawing systems.